Scale length and strings

- door Guy D'haenens

- •

- 15 aug, 2017

- •

You don't need muscular fingers to play the guitar

Some years ago, I was in a renowned guitar shop when I overheard a conversation between a young female guitarist and the shop owner who also happens to be a fine guitarist. She told him about the difficulties she had playing bar (barre) chords. His answer was that she’d have to practice more to enforce finger strength. Looking at his hands and large muscular fingers, it was obvious that he had no problems whatsoever with bar chords. Although I didn’t interfere, I felt that his answer was a bit short-sighted. Guitarists with small/tall and less muscular fingers can practise all day and yet never reach that level of ease with bar chords. IMO, he should have told here that she could go for a guitar with a shorter scale or for strings with less tension. That would have solved her problem.

Strings with less tension

Every guitar is set up for a particular string gauge. This gauge is an indication that the company or person who created the guitar thinks that with this particular gauge, the best sound is achieved and the risk of structural damage is minimized. You, the owner, may disagree and opt for a lighter or heavier gauge.

Light gauge strings will be more comfortable because they are easier to fret and bend. The opposite goes for heavy gauge strings: harder to fret and quite difficult to bend.

Another option is to stick with the same gauge but choose strings with less tension such as the well-known “Silk and Steel” strings or the Newtone Heritage strings which are designed to have a reduced and almost equal tension on each string.

When you start searching for strings with less tension, you will find that only a few string manufacturers publish tension tables. If you are fond of a certain brand, you might contact them directly and ask for advice.

You may find that by using strings with less tension, the action of the guitar (the height of the strings from the fingerboard at the 12th fret) is decreased and by using strings with more tension the action is increased. In both cases, you probably will have the truss rod adjusted and the saddle adjusted or replaced by a qualified repair person or guitar builder. Apart from that, switching gauges may also require the nut slots to be filled (lighter gauge = smaller diameter) or filed (heavier gauge = larger diameter). These adjustments are reversible and require only a small investment in time and/or money.

All this being said, putting strings with less tension on a guitar with heavy or even normal braces could be disappointing: because the strings have less mass and tension, the decreased transfer of energy to the top plate could result in a weak, tiny tone which even playing harder won’t solve. The positive news is that you won’t inflict any structural damage to your guitar.

I would definitely advise you against putting strings with higher tension on a guitar with normal or light braces. You will have a guitar with a strong tone and increased fundamentals but only for a short time. The immense pull of the strings will make the belly of the guitar swell with the risk of braces falling off (literally), the top plate cracking (presumably on both sides of the glue joint) and an action so high no truss rod adjustment can cure.

The golden rule is: only go 1 gauge up or down. If the recommended gauge for your guitar is 12, go no further than 11 or 13. If you are not sure about the recommendation, inspect the braces of your guitar or have them inspected by a luthier to see which gauge would be suited.

If changing strings is not satisfactory, start looking for a guitar with a short scale.

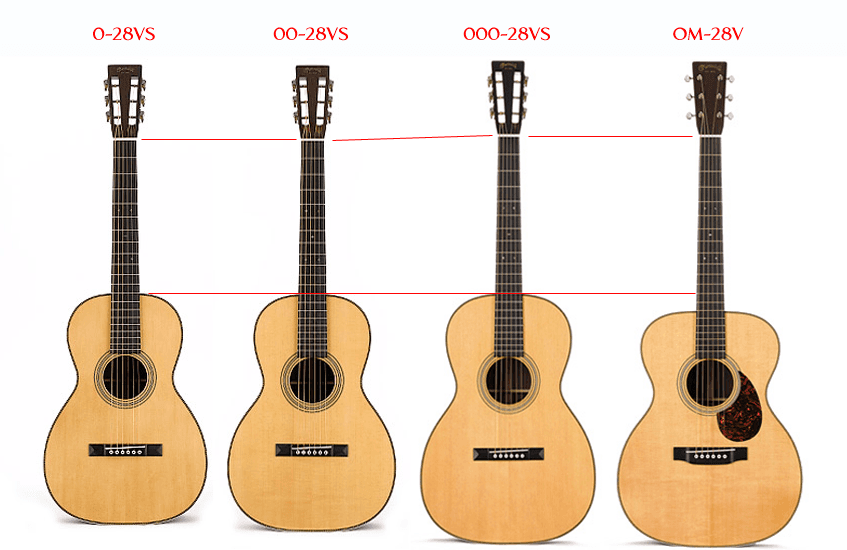

Short scale guitars

You can easily check how a short scale guitar feels by tuning the guitar half a note down (to D#A#F#C#G#D#) and putting a capo on the first fret. The increased comfort in fretting the guitar will be quite notable. If you don’t mind the capo, the fact that you’ll only have 11 frets from nut to body and in most cases a slightly weaker tone , this trick might just work for you.

But how comes that this 5.6% reduction in length has such a major effect on comfort?

Each string has to be tuned to a certain pitch. The longer the string, the more it has to be stretched to obtain that pitch. And by stretching a string, it becomes less flexible and thus harder to fret. It is that simple.

So why does everybody use larger scales then? Well, the answer is also simple: shorter and more flexible strings have the tendency to act more “floppy” which reduces the time they can exert force to the top plate and produce sound. A guitar with a longer scale will sound fuller and richer with more overtones than a guitar with a short scale. Unless… the short scale guitar was build by a good luthier.

Note that the scales of electric guitars are shorter than the scales of acoustic guitars. As electric guitars don’t rely on the transfer of energy to the top plate but on the changes in the magnetic fields of the pickups, they benefit hugely from “floppy” strings.

Where am I heading at? In a world where mass production is the only way to reduce costs, chances that you will come across a good sounding short scale mass production acoustic guitar in a shop are almost nil. There is simply not enough demand to justify the production setup nor the distribution. Fitting a shorter neck to a regular body simply won’t do, the body size too has to be slightly smaller and the braces have to be lighter and shaped differently.

In short: if you want a good sounding short scale guitar, contact a luthier. He or she can do wonders for you.

Guy's Blog

Guitars are designed for the 12-tone equal tempered tuning (12-TET). In a 12-tone equal tempered tuning, an octave is divided in 12 semitones at an equidistance of each other: C, C# or Db, D, D# or Eb, E, F, F# or Gb, G, G# or Ab, A, A# or Bb, B.

12-tone equal tempered tuning assumes that e.g. C# is soundwise exactly in the middle of C and D. As you could have guessed, in real life it’s not, it’s only in the mathematical middle and soudwise a bit on the sharp side.

Guitars and all other instruments are tuned at A4= 440 Hz. In 1939 musicians world-wide came to a consensus on that pitch. Before that time, the pitch had been 435 Hz, 374 Hz (1648) and 503 Hz (1361) but those were merely guidelines. Each maestro was free to compose or direct at a lower or higher pitch.

(Hz is the unit to express the number of oscillations of pressure in a sound wave. 440Hz means that there are 440 oscillations per second.)

When you pull an unfretted A-string on a tuned guitar, you’ll hear 110 Hz. When you fret that string at the 12th fret, you’ll hear 220 Hz. That’s exactly the double. Double or half the Hz of any tone is called an octave. Fret that string at the 24th fret and you’ll hear 440 Hz, again one octave higher or 2 octaves higher than the tone of the unfretted string. What you have done each time, is shorten the string by half. A shorter string vibrates at a higher speed thus producing more oscillations per second. A string at 440 Hz oscillates twice as fast as a string of double that length.

The guitar is fretted so we can easily pick the correct notes. Those frets are laid out according to a simple calculation.

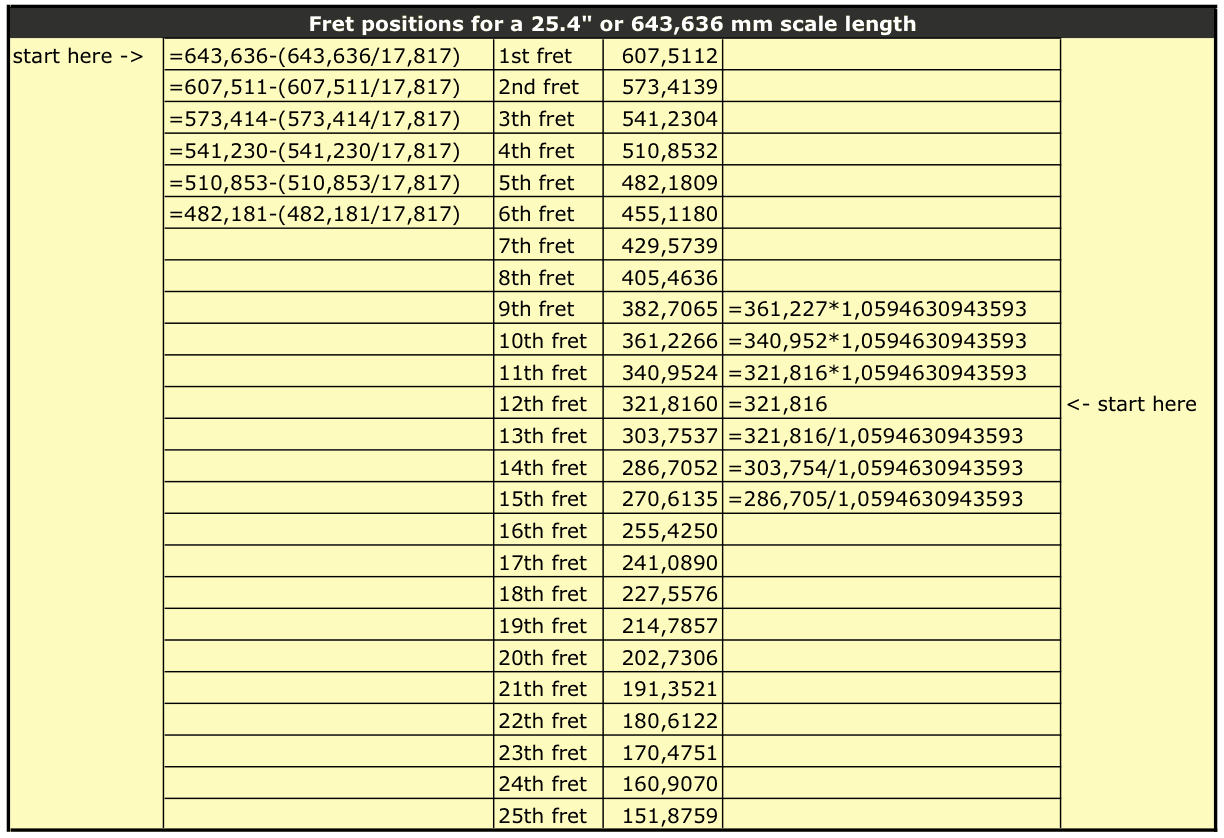

Assume that the scale length of your guitar is 25.4″ (actually it’s 25,34″) or 643,636 mm. The scale length is the distance between the nut and the top of the saddle. The 12th fret will be exactly at 12.7″ (25.4″/2) or 321,818 mm. And since an octave in a 12-TET scale is divided in 12 semitones at equidistance of each other, the math should be fairly simple, no? Alas, dividing 12.7″ by 12 won’t do. That is because we can’t use the distance as input for our calculations, we have to use the frequences. In a 12-TET scale, the ratio of frequencies between two adjacent semitones is the twelfth root of two. And the twelfth root of two is 1.0594630943593.

So starting from the 12th fret, the exact position of the other frets is easily calculated by multiplying or dividing the position of a (previous) fret with 1.0594630943593.

The position of the 11th fret is 340,9543 mm (321,818 * 1,0594630943593); the position of the 10th fret is 361,2626 mm (340,954294100521 * 1,0594630943593); that of the 13th fret is 303,7557 mm (321,818 / 1,0594630943593) and so on.

Another way to determine the fret positions is by using the constant 17.817. The scale length divided by this value gives us the distance from the nut to the first fret.

The following table will make it more clear: